The project

FibeCycle, working together with Nergica, has recently undertaken a detailed study on the carbon footprint of wind turbine blades throughout their life cycle. The partnership highlights the positive impact of recycling composite materials used in wind turbines, offering an innovative solution for reducing waste and promoting a sustainable future.

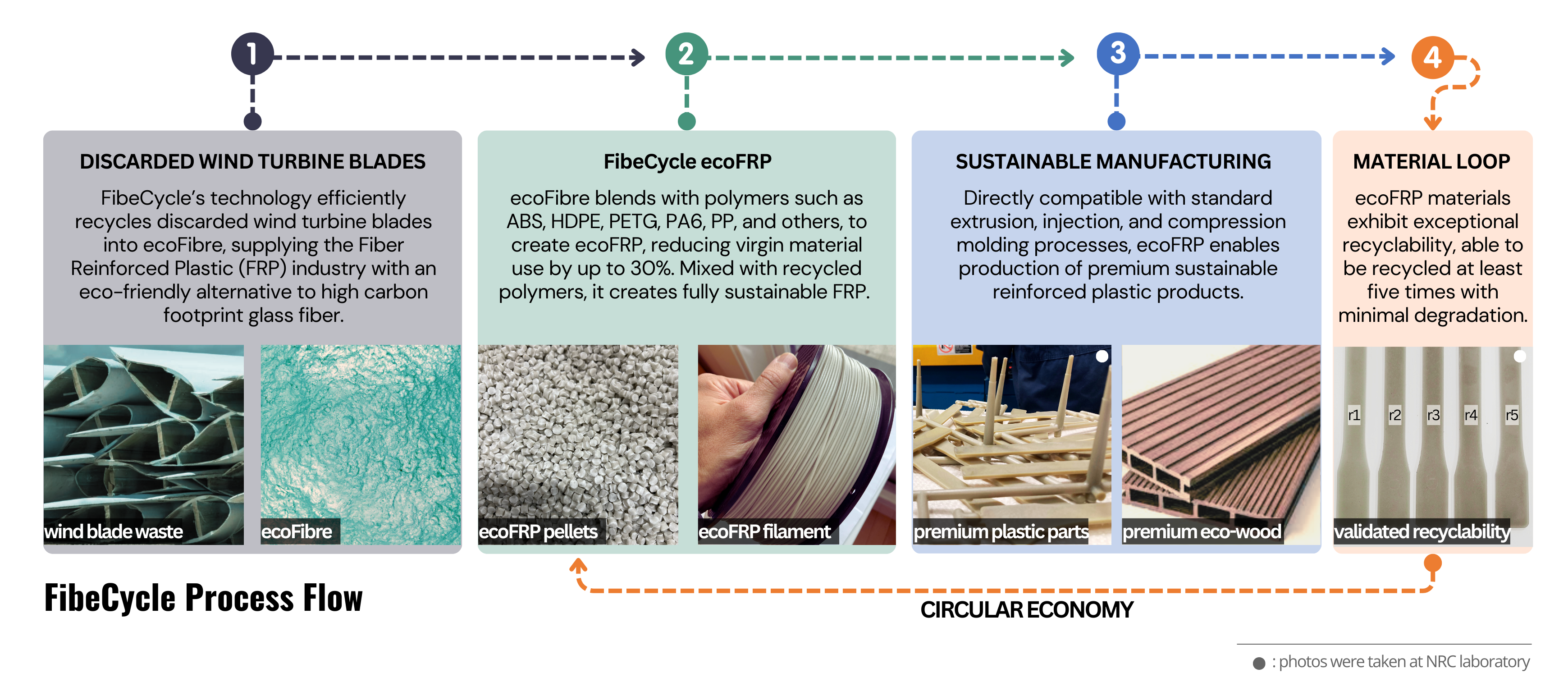

FibeCycle shows that wind turbine blades can in fact be transformed into new environmental resources. At FibeCycle, we often say that we are revolutionizing how people perceive wind turbine waste. Once deemed non-recyclable, turbine blades are now being successfully recycled through our innovative processes. We are not just shifting the conversation; we are demonstrating that recycling turbine blades is not only feasible but also highly effective” says Cesar Patricio, cofounder and CEO of FibeCycle. “Our exclusive and innovative recycling process is geared to adjust to demand, while efficiently transforming large volumes of discarded wind turbine blades,” he adds. The blade recycling process developed by FibeCycle involves a comminution procedure followed by a sophisticated fibre sorting stage, transforming it into high-quality recycled fibreglass. This fibre is then used to create fibre-reinforced polymers (ecoFRPs[1]), making it possible to manufacture sustainable products while reducing dependence on virgin materials.

Photos of the FibeCycle process show the transformation from discarded blades to the manufacture of eco-friendly materials.

Meeting the challenge

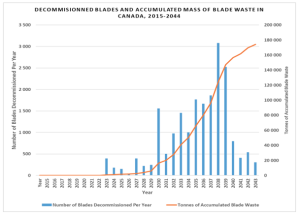

The numbers are striking: Approximately 174,000 tonnes of wind turbine blade waste will be generated in Canada over the next 20 years. Projections indicate that blade waste generation will peak between 2036 and 2040, reaching a maximum of 29,000 tonnes per year in 2038. Without an efficient recycling solution, this amount of waste will end up amplifying environmental issues. FibeCycle’s technology thus offers a proven alternative by promoting a circular economy and lowering the carbon footprint of the wind turbine industry. Given the rising number of Canadian wind turbines reaching the end of their life cycle, finding sustainable solutions to recycle and reuse blade materials within a circular economy is vitally important.

The solutions

A typical 1.5 MW wind turbine contains approximately 23 tonnes of blade material, mainly fibreglass, resin, and adhesives. According to the Nergica team’s research, the turbine’s life-cycle energy consumption totals 646 Gigajoules, enough to power a small town’s Christmas lights for the holiday season. This process also results in a carbon footprint of 33.8 tonnes of CO2-eq, with 89% of emissions occurring during the manufacturing phase.

FibeCycle aims to transform this challenge into an opportunity by offering a viable recycling solution, lowering carbon emissions, and promoting environmental sustainability.

Key facts

- FibeCycle and Nergica have identified the significant carbon footprint of wind turbines, highlighting the need for recycling solutions.

- FibeCycle’s process transforms wind turbine blades into high-quality recycled fibreglass, creating fibre-reinforced polymers (ecoFRPs).

- In 2038, Canada will decommission around 3081 wind turbine blades, generating more than 29 000 tonnes of blade waste. Without recycling solutions, this waste would have a devastating environmental impact.

- FibeCycle’s approach reduces dependence on virgin materials, contributing to the circular economy in the renewable energy sector.

- The recycling of wind turbine blades supports the commitment to green energy and the reduction of CO2 emissions, responding to a major environmental concern.

About us

FibeCycle

FibeCycle was founded to help address the issue of wind turbine blade end-of-life. The company’s solution provides a sustainable alternative that effectively manages the disposal of wind turbine blades, which are typically made primarily of fibreglass. Instead of ending up in landfills or being incinerated, FibeCycle recycles these blades to create ecoFRPs (fibre-reinforced polymers) that are building blocks for creating sustainable products. The company’s approach focuses on recycling, reducing, and reusing wind turbine blade waste, fostering a sustainable circular economy.

Nergica

Nergica is a centre of applied research that stimulates innovation in the renewable energy industry through research, technical assistance, technology transfer and technical support for businesses and communities. Its mission is to accelerate the development and adoption of renewable energies. Nergica specializes in developing solutions for integrating renewable energies into the grid, optimizing the performance of wind and solar power plants, and supporting the growth of SMEs. Nergica has been active for more than 20 years in the field of renewable energy.

[1] EcoFRPs are sustainable composite materials derived from recycled fibres and resins